The world's only portable and visual solution for more efficient production

Connect in minutes.

Detects variations and stops,

saves film and sends facts mobile

Eye at Production is practically the world's only mobile, visual system with direct analysis that can be quickly connected to a machine or production line in just a few minutes. Our cameras detect micro-stops, faults and variations in real time and automatically save film that is connected to a dashboard. There, availability is analyzed and a basis for concrete improvements is created.

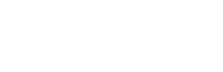

Eye at Production technology and service packages

Our technology and associated services are adapted to meet both large and small production needs.

Observer sees and

gives you control

Smart camera with remote control

for recording and saving

of deviations and stops.

Expert sees, understands for himself

and gives you more control

Everything Observer has plus

automatic registration and

digital dashboard

Guru sees, understands and

gives you full control

Everything Observer and Expert have plus

more integrations, broader monitoring,

sensors and dashboards

Identifies deviations, bottlenecks and

unplanned stops. Mobile, visual and smart.

Eye at Production monitors automated flows such as robot cells,

product and packaging lines and registers deviations visually and fully

automatically. Increases availability, reduces costs and saves resources.

Mobile & intelligent monitoring

Automatically records faults &

deviations

Notes, saves,

collects & analyzes

Adapted for all kinds of production

The system works in everything from precision-controlled detail environments to highly automated

manufacturing lines and pick & place processes. It handles complex

flows, calculates cycle and wait times in real time, tracks visual details

Tomorrow's surveillance is

visual, mobile and smart.

Visual monitoring with calculations and analysis in real time provides full control and

knowledge for enormous efficiency improvements and savings.

The solution for production stop

Optimize your OEE

Mount Eye at Production at the production line, packaging line, pick and place robot, palletizer or elsewhere in production where you suspect deviations, stops or bottlenecks. Also an important tool for accessibility analyses, LEAN and GEMBA.

Here you use Eye at Production

The demands in the industry are only getting higher and the processes must be efficient. Eye at Production is installed anywhere in the production, detects stops in the flow, shows relevant clips and is easy to use. Quick to assemble, flexible to move around.

Recurring stops:

Faults can occur in a variety of places. Eye at Production is mounted anywhere on the production line to identify stoppages.

Recurring quality deviations:

A robot may need to be adjusted or a product is misplaced on the belt. Eye at Production finds the reason for the discrepancy.

PLC:

What is the reason for the recurring fault? Set Eye at Production to what it should register and you will soon know the reason.

Palletizer:

Did the product enter the wrong position or was it the robot that placed it incorrectly on the pallet? With Eye at Production you see exactly what happened.

Micro stop:

The proportion of expensive micro-stops in production lines is almost always more than industries think. Discover, analyze and eliminate them.

Bottleneck analysis:

Eliminating bottlenecks is important in all industries. With Eye at Production you get material to analyze cycle times, throughput and waiting times.

Health check:

Eye at Production allows you to easily move around the production just to make cuts and see that everything is working as it should.

Availability analysis:

Lack of availability in production can be due to a high percentage of unplanned downtime. Eliminate them using Eye at Production.

GEMBA:

With one or more Eye at Production around the production, you get film material to get close to the industrial process and make it more efficient.

Installations:

When installing new machines, stations, cells, palletizers or robots, it is important to be able to monitor the use during the first period.

That's how much you save with Eye at Production

You save

Stop time/day

- Minutes

SEK/month

- SEK

Stop time/year

- Hours

SEK/year

- SEK